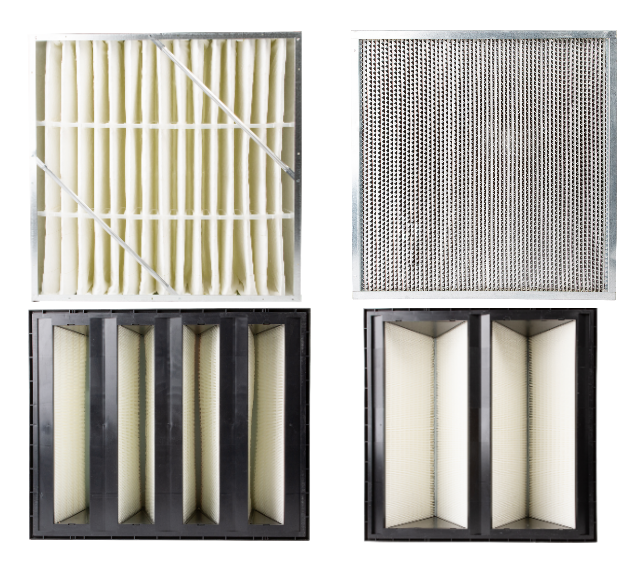

Box Style Air

Rigid

A rigid box filter frame boasts a rigid construction made using 26 gauge galvanized steel. A heavy gauge, galvanized steel header is optional. The media is a high density synthetic fiber or a microfine glass fiber. The filter media pack is constructed by pleating a continuous sheet of media into uniform spaced pleats, which are separated by flame retardant, injection molded plastic media separators. A heavy-duty expanded metal reinforcement is laminated to the air exit side of the media by a thermo-setting adhesive to maintain continuity of the radial pleats. The expanded metal is also galvanized to resist rust and corrosion. Metal vertical brackets is utilized to stabilize the media pack and prevent air bypass. The air entry and air exit side is fitted with two 26 gauge support struts and the pleated media ends are sealed to the top and bottom of the metal frame to prevent air bypass. These filters have been rated to withstand temperatures up to 180 degrees Fahrenheit.

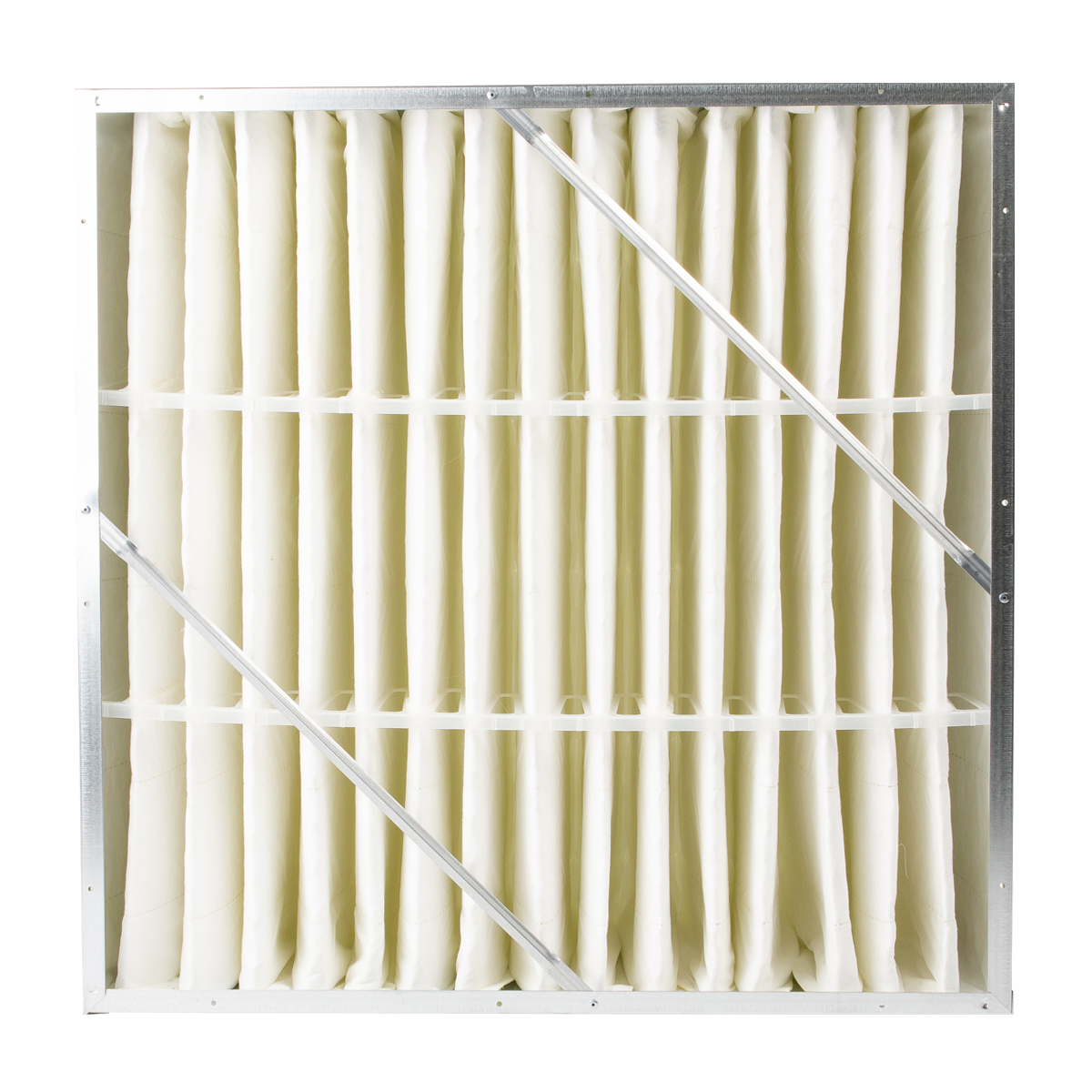

Extended Media Rigid

The frame shall be made of a 26-gauge galvanized metal frame is used for Extended Media Rigids. The media shall be constructed of a water-resistant, inorganic glass microfiber. For quality assurance, the glass microfiber media rolls are randomly tested and certified to meet minimum efficiency requirements by the media manufacturer. The media pack shall consist of a continuous sheet of the pleated glass microfiber. The pleated media pack is separated with multiple rolled-edge corrugated aluminum separators. The media cartridge shall be sealed with a fire-retarding, rubber base, two-part sealant that bonds the media and separators to the interior of the frame. A 1/4” thick closed cell neoprene gasket shall be applied on the filter. The filter shall be rated to withstand temperatures at a continuous 180° Fahrenheit.

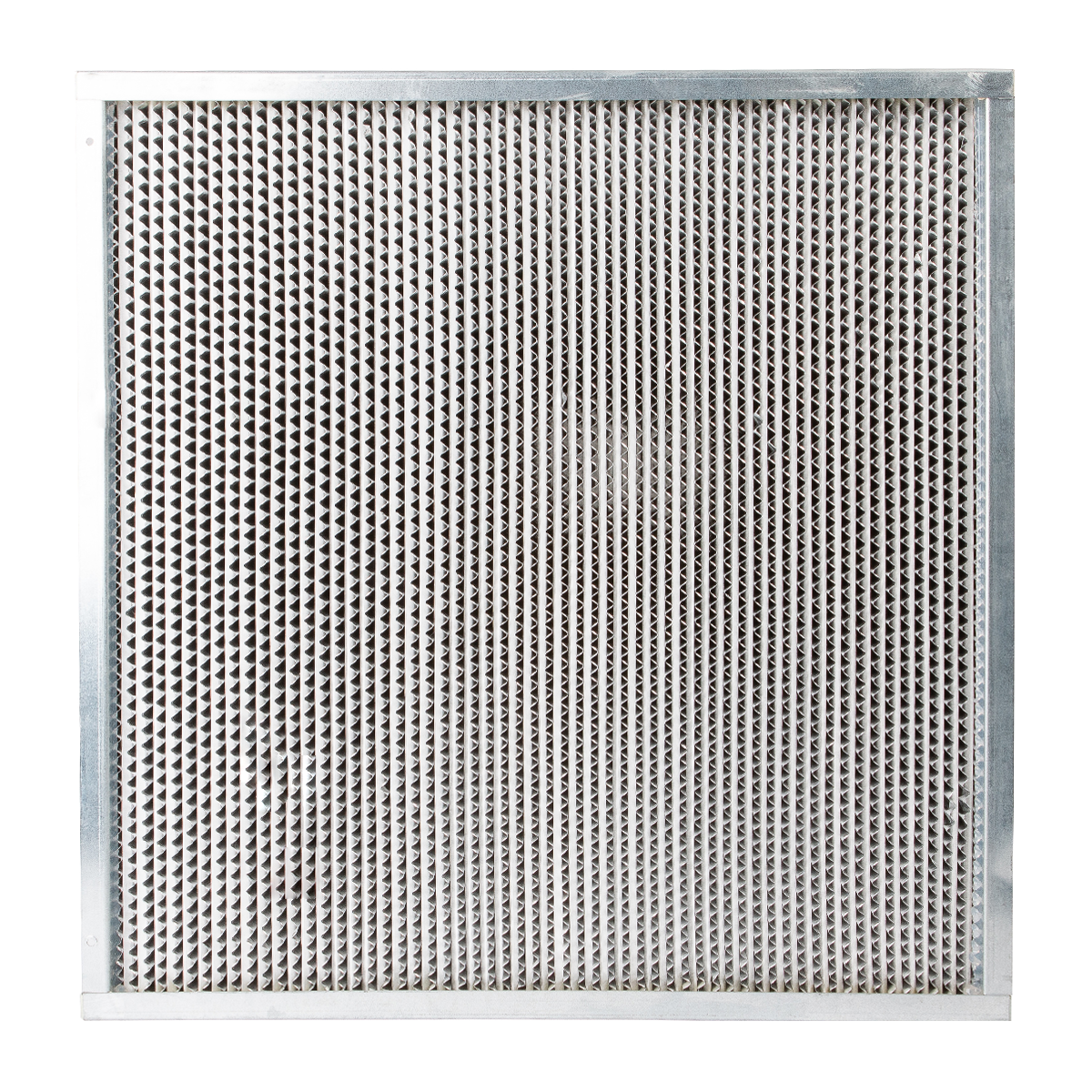

2V

4V

The Right Filtration for Every Application

Our experts help you select the ideal product to enhance air quality, protect critical equipment, and maintain operational efficiency.